濟(jì)南濟(jì)柴環(huán)能燃?xì)獍l(fā)電設(shè)備有限公司

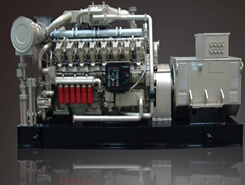

—— 燃料發(fā)電設(shè)備及機(jī)組相關(guān)配套設(shè)備及配件 ——

—— 燃料發(fā)電設(shè)備及機(jī)組相關(guān)配套設(shè)備及配件 ——

全國服務(wù)熱線:

全國服務(wù)熱線:

全國服務(wù)熱線:

全國服務(wù)熱線:

濟(jì)南濟(jì)柴環(huán)能燃?xì)獍l(fā)電設(shè)備有限公司

濟(jì)南濟(jì)柴環(huán)能燃?xì)獍l(fā)電設(shè)備有限公司

聯(lián)系電話:羅總18653152416

服務(wù)熱線:0531-62325028

聯(lián)系地址:中國(山東)自由貿(mào)易試驗(yàn)區(qū)濟(jì)南片區(qū)孫村街道經(jīng)十東路33688號章錦綜合保稅區(qū)聯(lián)東U谷科創(chuàng)中心5號樓101

掃一掃了解更多

掃一掃了解更多